High-speed 3D laser line profile sensors play a vital role in car manufacturing, particularly in quality control and inspection processes. These sensors use laser technology to capture precise 3D measurements of car components and surfaces, enabling manufacturers to ensure dimensional accuracy and detect any defects or variations in the produced parts.Here are some key features and applications of high-speed 3D laser line profile sensors in the automotive industry:

- Fast and Accurate Measurements

These 3D laser line profile sensors employ advanced laser triangulation techniques to rapidly capture high-resolution 3D measurements, providing accurate dimensional data of car body panels, doors, windows, gaps, and other critical components.

- Quality Control and Inspection

High-speed 3D laser line profile sensors are employed for quality control and inspection tasks throughout the automotive manufacturing process. They can measure and analyze the dimensions, contours, and surface characteristics of components such as body panels, doors, engine parts, and other critical parts. These sensors assist in identifying defects, surface imperfections, variations in part dimensions, and ensuring compliance with design specifications. This enables immediate feedback and corrective actions, reducing the risk of producing faulty or non-compliant parts.

- Reverse Engineering

Automotive manufacturers use high-speed 3D laser line profile sensors for reverse engineering applications. These sensors can quickly capture the shape and geometry of existing parts or components, allowing manufacturers to create accurate digital models for further analysis and replication. Reverse engineering is essential for designing aftermarket parts or modifying existing components.

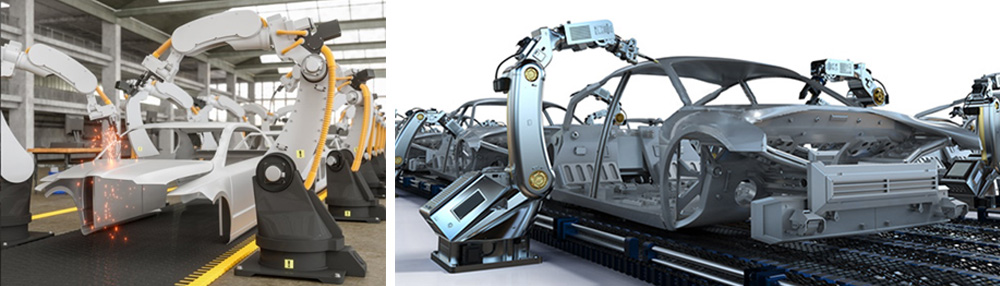

- Robotics and Automation

High-speed 3D laser line profile sensors play an integral role in automotive robotics and automation systems. They provide real-time, high-precision measurements to guide robots in tasks such as picking, placing, and assembly of automotive parts. These sensors enable robots to perceive and adapt to variations in object positions, shapes, and orientations, facilitating efficient and accurate automation processes.

- Body-in-White Inspection

The Body-in-White (BIW) stage of automotive production involves inspecting and verifying the fit and alignment of body components before final assembly. High-speed 3D laser line profile sensors are used to measure key features such as gaps, flushness, and alignment of doors, hoods, fenders, and other body panels. This ensures optimal fit and finish, reducing manufacturing defects and improving overall quality.

- Surface Defect Detection

High-speed 3D laser line profile sensors are capable of detecting and quantifying surface defects such as dents, scratches, and waviness on automotive components. By capturing precise surface profiles, these sensors enable manufacturers to identify flaws early in the production process, leading to improved product quality, reduced rework and minimizing scrap.

- Inline Measurement and Process Control

High-speed 3D laser line profile sensors can be integrated into production lines to provide real-time measurements for process control. By continuously monitoring critical dimensions and tolerances, these sensors enable manufacturers to detect deviations and make necessary adjustments to ensure consistent quality and adherence to specifications.

- Metrology and Alignment

Laser line profile sensors help in metrology applications by providing precise measurements for alignment, gap and flushness analysis, and dimensional verification. This is crucial for ensuring proper fit and finish in car assembly processes.

In summary, high-speed 3D laser line profile sensors play a vital role in the automotive industry for accurate measurements, quality control, inspection, reverse engineering, robotics, automation, surface defect detection, process control and metrology alignment. These sensors enable precise dimensional measurements, surface analysis, and accurate 3D modeling, contributing to improved manufacturing efficiency, quality assurance, reduce cost and product innovation in the automotive sector.