In industries that rely on precise measurements, having the right tools is essential for success. RSTC long distance laser sensor provides a reliable option for businesses seeking to improve their measurement capabilities. These sensors are designed to deliver accurate readings, making them valuable assets in various applications, from construction to manufacturing.

Understanding the Functionality of Distance Sensors

A distance sensor measures the specific size and surface defects of the object under test by XYZ triaxial measurement. RSTC’s distance sensors leverage advanced technology to ensure this kind of measurements, which are critical for effective project management and quality assurance. Real-time data from these sensors allows for better monitoring facilitating smoother operational workflows.

Key Features of RSTC Laser Line Profile Sensors

RSTC laser line profile sensors are engineered for high performance. One of their main advantages is their ability to measure distances accurately over extended ranges. This feature is especially useful for large-scale projects where traditional sensors might not suffice. By using RSTC laser line profile sensors, businesses can obtain reliable data without the need for multiple devices, simplifying measurement tasks.

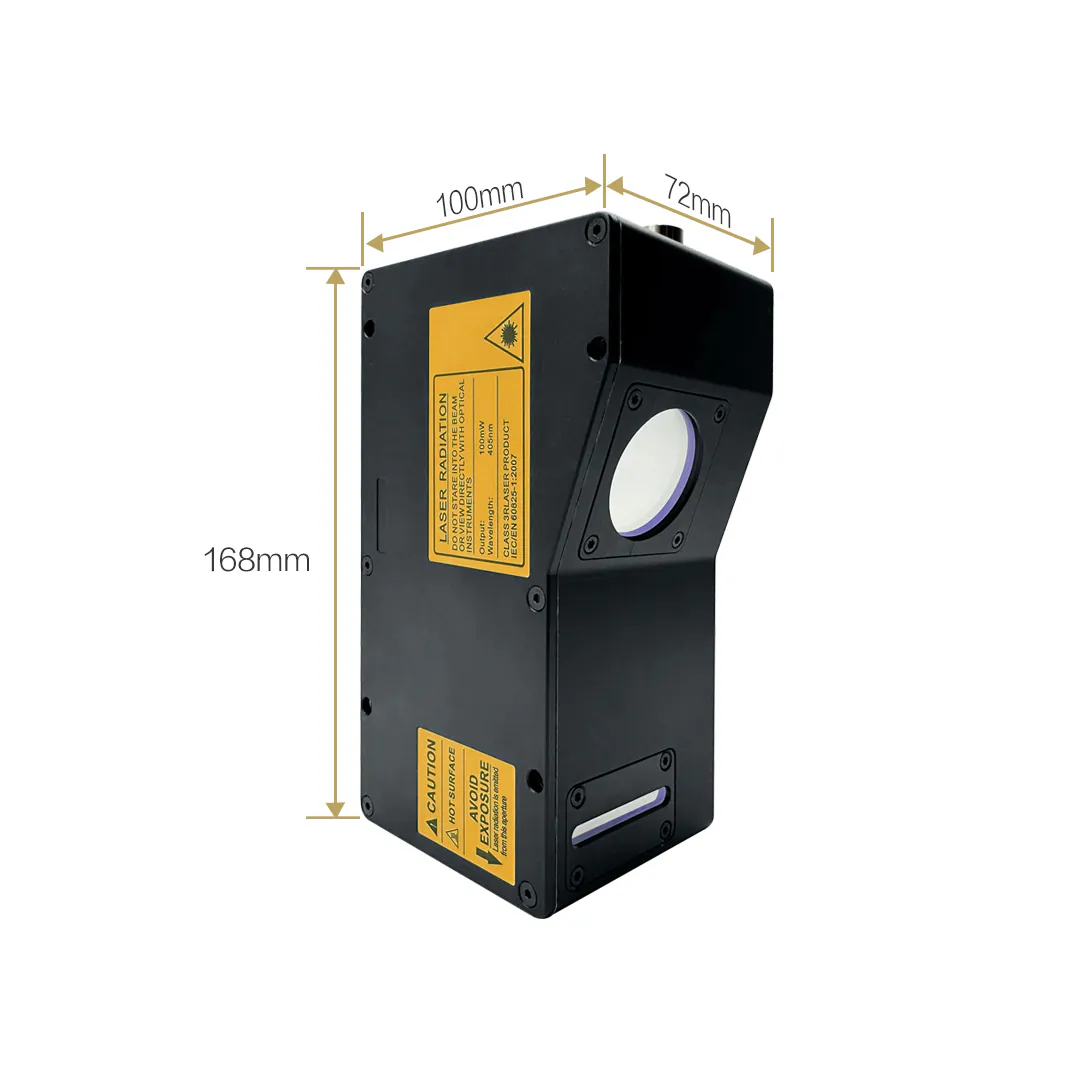

These sensors are also designed to be robust and durable, ensuring consistent performance in various environmental conditions. This reliability is essential for minimizing errors and maintaining quality standards in operations. RSTC’s commitment to quality is evident in the construction and technology used in their sensors.

Versatile Applications in Various Industries

The applications for RSTC distance sensors are broad and varied. In construction, these sensors can help with measuring distances for site layouts, ensuring materials are positioned correctly. In manufacturing, they assist in monitoring the placement of components on assembly lines, which enhances workflow efficiency and reduces the risk of errors. In logistics, laser line profile sensors play a vital role in optimizing national defense, smart factory, automation and so on. The versatility of RSTC sensors makes them suitable for a wide range of tasks across different sectors.

Improving Operational Efficiency

Integrating RSTC laser line profile sensors into operational workflows can lead to significant efficiency improvements. Their ability to provide accurate measurements allows for quicker decision-making and reduces the likelihood of mistakes. This efficiency is crucial for maintaining productivity and ensuring that projects are completed on schedule.

Moreover, RSTC’s sensors can be easily integrated into existing systems, allowing businesses to enhance their measurement capabilities without major disruptions. This ease of integration makes RSTC a practical choice for organizations looking to upgrade their technology.

Conclusion

Choosing RSTC laser line profile sensors is a sensible decision for organizations focused on enhancing measurement accuracy and operational efficiency. By leveraging their advanced distance sensor technology, businesses can improve their measurement capabilities, streamline processes, and achieve better results in their projects. RSTC technology provides a reliable solution for meeting the measurement needs of today’s industries.