3D Visual Intelligence

Empower Your Factory with 3D Profile Sensors

3D Visual Intelligence

-

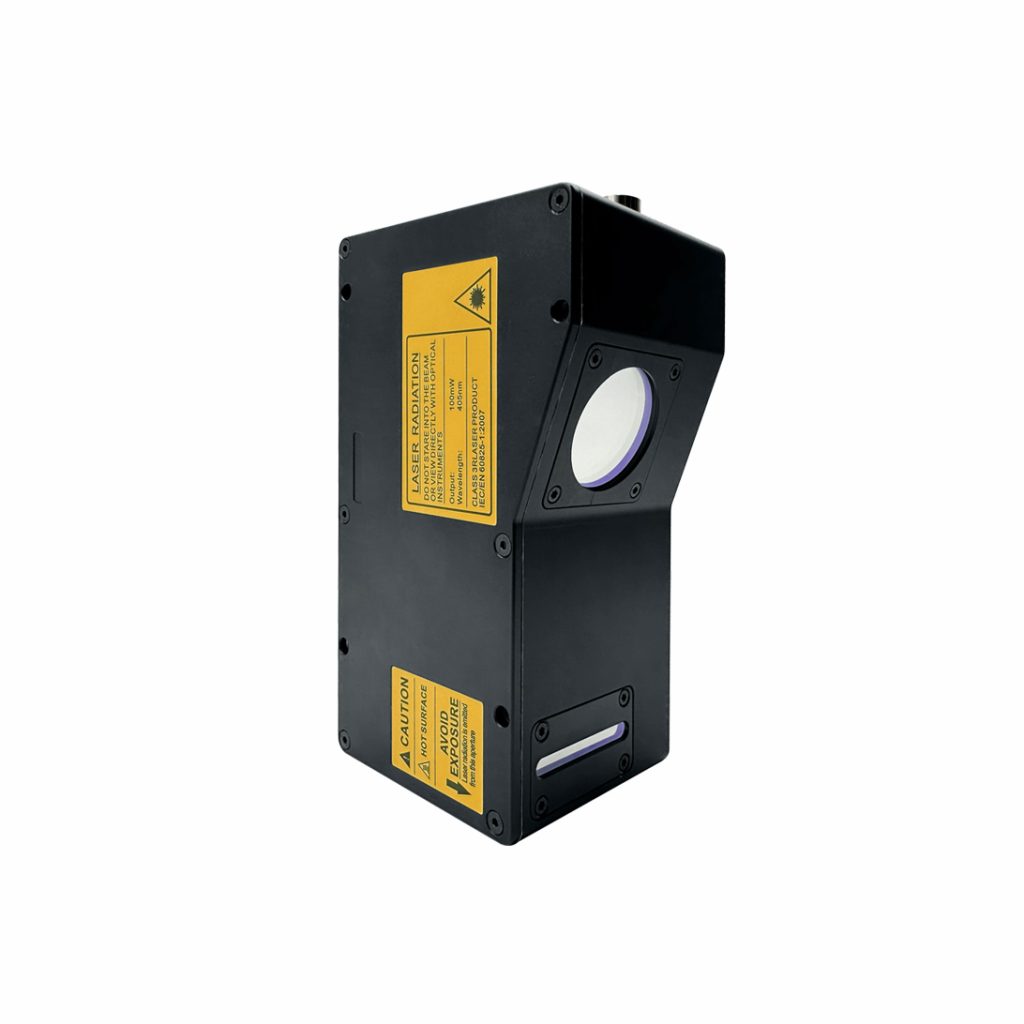

RGX-6020 High-Speed 3D Laser Line Profile Sensors (Measuring Range (CD) 20mm)

-

RGX-6055 High-Speed 3D Laser Line Profile Sensors (Measuring Range (CD) 55mm)

-

RGX-6150 High-Speed 3D Laser Line Profile Sensors (Measuring Range (CD) 150mm)

-

RGX-6300 High-Speed 3D Laser Line Profile Sensors (Measuring Range (CD) 220mm)

-

RGX-6600 High-Speed 3D Laser Line Profile Sensors (Measuring Range (CD) 555mm)

Understanding 3D Laser Profilers: Principles and Applications

What is a 3D Profile Sensor?

A 3D profile sensor is used to capture and measure the three-dimensional shape or profile of an object or a scene. These laser sensors are widely used in industries like factory automation, robotics, quality control, logistics, and surface inspection. By emitting light or other forms of energy and measuring the time it takes for the energy to bounce back, these sensors create precise 3D representations of objects.

How Do 3D Profile Sensors Work?

3D laser line profile sensors leverage advanced technologies such as laser triangulation, structured light, ToF (Time-of-Flight), and stereo vision to measure depth and generate detailed 3D profiles. Here’s a simplified breakdown of each approach:

- Laser Triangulation: A laser beam is projected onto the object's surface, and a camera captures the reflected light. By measuring the angle of the reflection and knowing the positions of the laser and camera, the sensor calculates the distance to each point on the surface, generating a 3D point cloud.

- Structured Light:A light pattern, such as a grid or series of lines, is projected onto the object. The sensor analyzes how the pattern deforms on the surface to calculate the depth of each point, creating a 3D profile.

- Time-of-Flight (ToF): 3D laser profile sensorsemit light pulses and measure the time it takes for the light to travel to the object and back. This data is used to calculate the distance to the object’s surface, creating a 3D representation.

- Stereo Vision: Using two or more cameras, 3D profile measuring sensors capture images from different angles. By comparing the images, the sensor calculates the distance to the surface and reconstructs the 3D profile.

These technologies provide precise 3D measurements, making 3D laser profilers ideal for high-accuracy applications requiring detailed surface analysis.

Laser Profiler Case Studies

3D Laser Line Profile Sensors are used in a wide range of industries where high-precision surface measurement, shape analysis, and quality inspection are essential. Some of the key application areas include:

- Industrial automation: In automation, 3D profile sensors are used for real-time monitoring and quality control of production lines, ensuring that every product meets strict quality standards.

- Automotive: In the automotive industry, 3D laser profile sensors are used for quality inspection of parts, surface defect detection, dimensional measurements, and assembly accuracy checks.

- Electronics Manufacturing: For PCB and electronic component production, 3D laser profile sensors detect dimensional variations, solder joint quality, and component surface defects, ensuring production consistency.

- Metal Processing: In metal industries, 3D laser profilers inspect surface conditions, measure material thickness, and verify dimensional accuracy during processes like casting, rolling, and welding.

These industries require high precision for dimensional measurements, surface defect detection, and quality control, making 3D laser profilers indispensable tools.

| Sensor Type | Typical Applications |

|---|---|

| 3D Profile Sensor | General-purpose 3D profile measurement in various industrial environments |

| Laser Line Profile Sensor | High-speed inline inspection, dimensional control, and defect detection on production lines |

| 3D Laser Profilometer | High-precision surface roughness and flatness analysis in laboratory or quality control settings |

| 3D Measurement Sensor (ToF) | Large-object scanning, edge detection, and coarse 3D measurements |

| Laser Profiler Sensor / 3D Profiler System | Automated assembly line inspection and integrated industrial measurement systems |

Features of RSTC 3D Laser Line Profile Sensors

- High-speed scanning: Capable of full-frame scanning speeds up to 64,000Hz, perfect for dynamic, real-time measurements in fast-paced environments.

- Omni-directional measurement: Automatically covers a wide field of view across the X, Y, and Z directions, ensuring comprehensive data capture across multiple axes.

- High accuracy: Utilizes laser triangulation for precise real-time height, width, and length measurements, making it perfect for high-precision distance sensors.

- Strong environmental adaptability: The linear laser solution doesn’t rely on physical texture, providing stable performance in varied environments and overcoming imaging challenges common in traditional distance measuring sensors.

- High resolution: Equipped with 3200 dots ultra-high resolution, it ensures even the smallest dimensional changes are detected, making it essential for 3D laser profile sensors.

- Software platform support: Comes with a dedicated 3D measurement software platform for efficient data processing and analysis, enhancing the performance of 3D laser line profile sensors in complex applications.

With these innovative features, the RSTC 3D Laser Line Profile Sensor distinguishes itself as a dependable option for sectors requiring accurate and versatile measuring systems.

3D Profile Sensors OEM & ODM Service

At RSTC, we offer more than just standard products – we provide OEM and ODM services designed to meet your specific needs. Our team ensures each product is optimized for high performance, seamlessly integrating with your systems. Additionally, we operate a dedicated lab for scanning materials for inspection, which helps evaluate whether our 3D laser line profile sensors can deliver real value for Industry 4.0 smart manufacturing. You can rely on us to deliver 3D profile measuring sensors that precisely match your needs and support the accomplishment of your corporate goals. We would love to help you if you need anything.